Overview

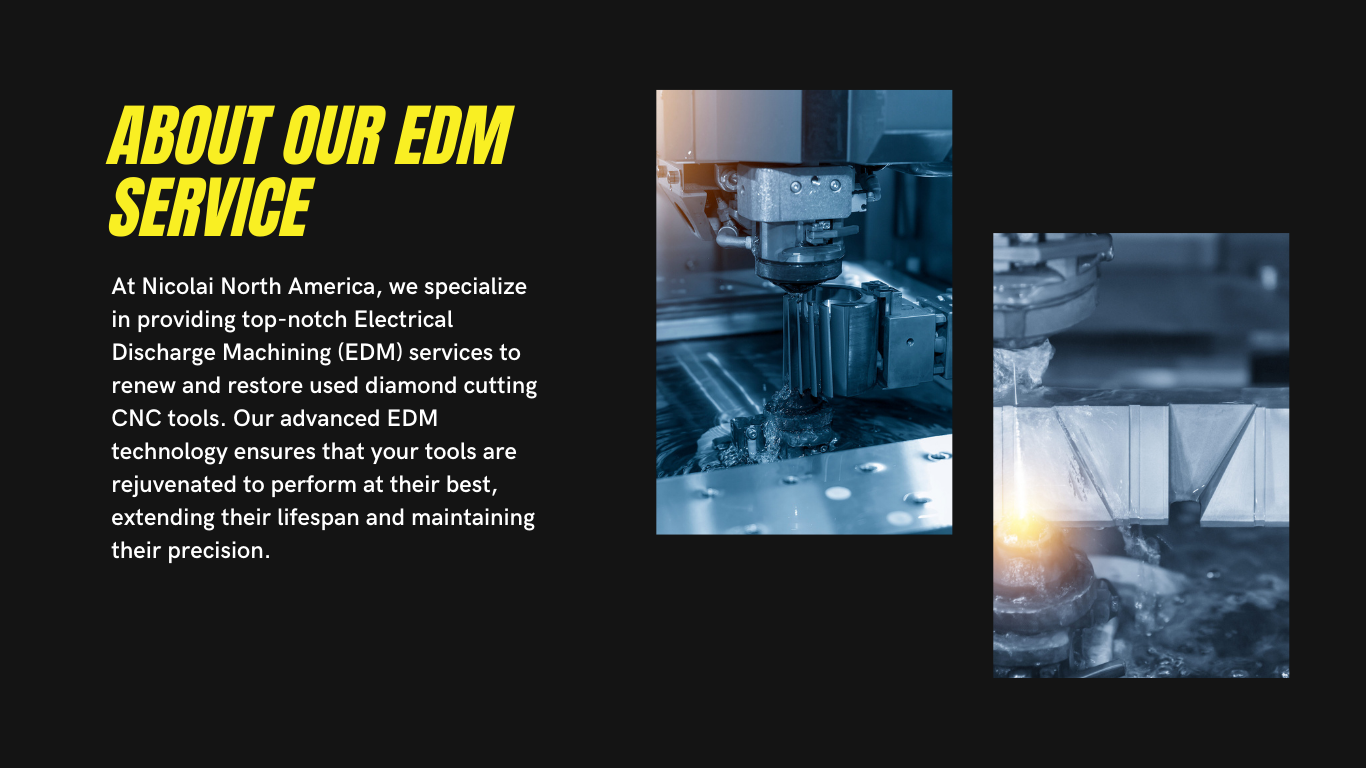

At Nicolai North America, we specialize in providing top-notch Electrical Discharge Machining (EDM) services to renew and restore used diamond cutting CNC tools. Our advanced EDM technology ensures that your tools are rejuvenated to perform at their best, extending their lifespan and maintaining their precision. By leveraging our expertise and cutting-edge equipment, we help you maintain optimal performance and productivity in your machining operations.

What is EDM?

Electrical Discharge Machining (EDM) is a non-traditional machining process that uses controlled electrical discharges (sparks) to shape and alter materials. This method is particularly effective for hard and electrically conductive materials such as diamond. Unlike traditional machining techniques that involve physical contact between the tool and the workpiece, EDM is a contact-free method. This lack of direct contact significantly reduces wear and tear on both the tool and the workpiece, ensuring high precision and longevity. EDM is widely used in industries requiring intricate and precise machining, such as aerospace, automotive, and tool and die manufacturing.

Our EDM Services

Tool Inspection and Assessment

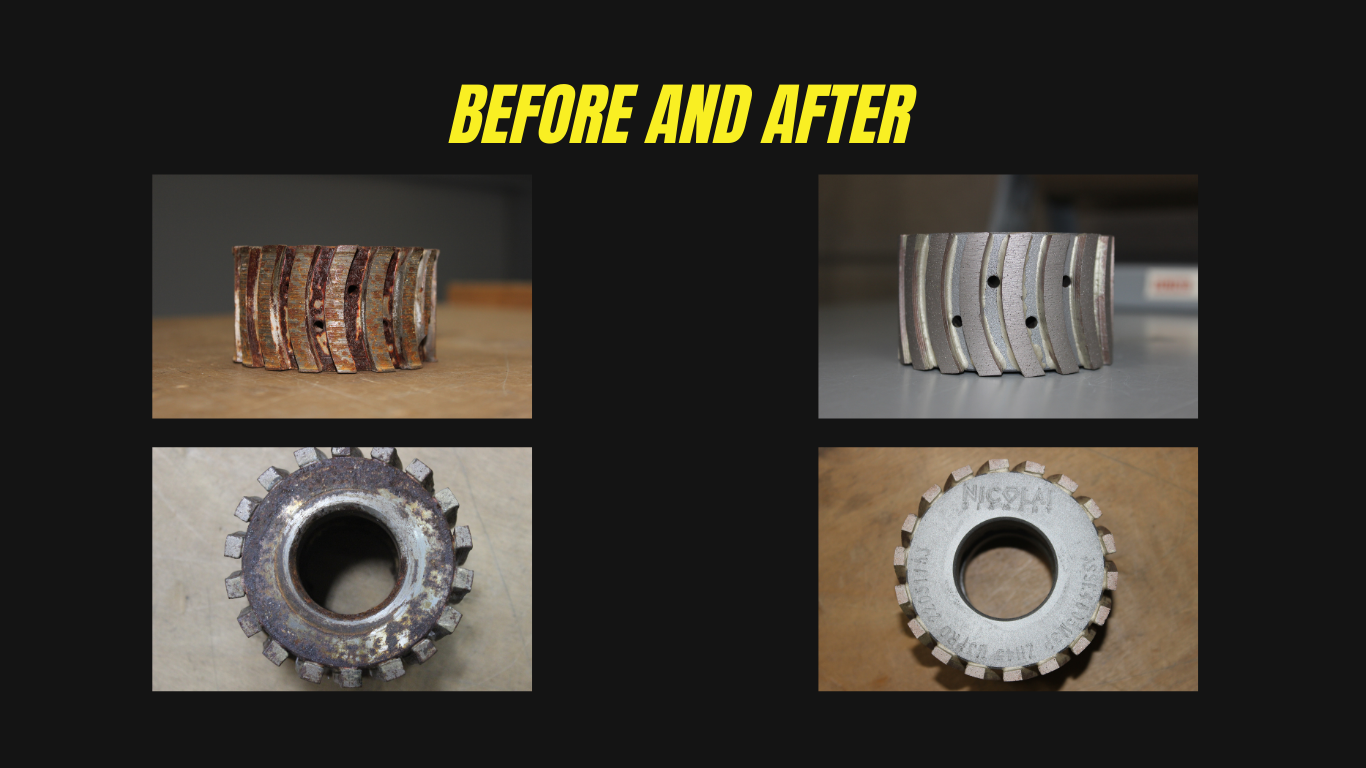

Before we begin the EDM process, our team of experts conducts a thorough inspection and assessment of each used diamond cutting CNC tool. This initial step is crucial as it helps us determine the extent of wear and damage, allowing us to plan the most effective rejuvenation process. Our comprehensive inspection includes checking for surface wear, edge sharpness, structural integrity, and any other signs of damage that may affect the tool’s performance. By understanding the specific condition of each tool, we can tailor our EDM services to address its unique needs.

Precision Reconditioning

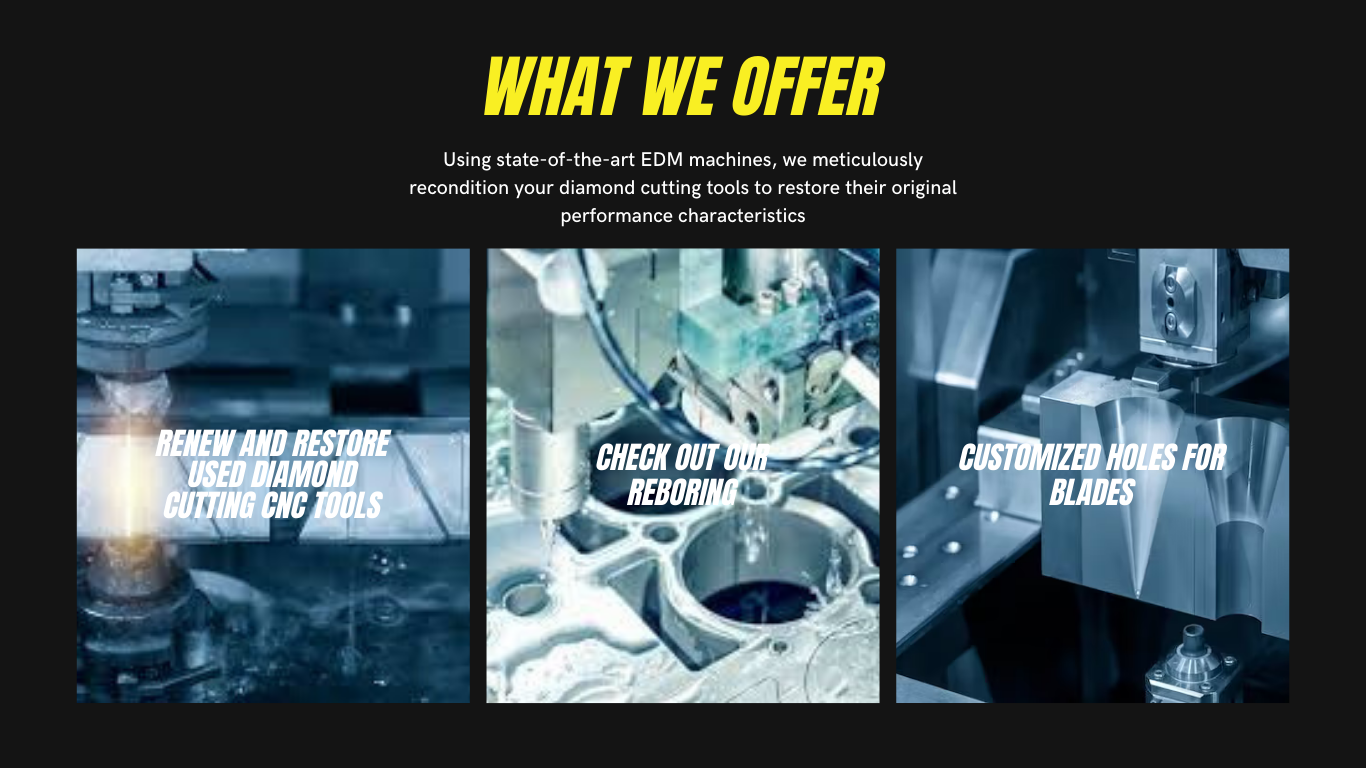

Using state-of-the-art EDM machines, we meticulously recondition your diamond cutting tools to restore their original performance characteristics. Our precision reconditioning process involves several key steps:

- Spark Erosion: We use controlled electrical discharges to remove worn or damaged material from the tool. This process allows us to reshape the tool with precision, ensuring it meets or exceeds its original specifications.

- Surface Finishing: The EDM process results in a smooth and refined surface finish, which enhances the cutting performance and accuracy of your tools. This step is critical in reducing friction and wear during use.

- Dimensional Accuracy: Our advanced EDM technology ensures that the restored tools maintain tight dimensional tolerances, providing you with tools that perform like new. This accuracy is essential for maintaining consistency and quality in your machining operations.

- Reboring: To enhance the fit and functionality of your tools, we offer reboring services. Reboring ensures that your tools fit perfectly on your machines, reducing vibration and improving cutting precision. This process involves enlarging or reshaping existing holes to match the specific dimensions required by your equipment.

- Customized Holes for Blades: Based on your specific requirements, we can create customized holes for blades. These customizations allow for better functionality and compatibility with your equipment, ensuring optimal performance. Whether you need specific hole patterns, sizes, or shapes, we can accommodate your requests to meet your unique needs.

Quality Assurance

Quality is our top priority at [Your Company Name]. Each tool undergoes rigorous testing and inspection after the EDM process to ensure it meets our high standards. Our quality assurance process includes:

- Dimensional Verification: We verify that all dimensions are within specified tolerances using precise measurement tools.

- Performance Testing: Each tool is tested under simulated working conditions to ensure it performs as expected.

- Surface Inspection: We inspect the surface finish to ensure it is smooth and free of defects.

We guarantee that your renewed tools will offer exceptional performance and durability, providing you with reliable and consistent results in your machining operations.

HAVE A QUESTION?

Send Us a Message Here!

Benefits of Our EDM Services

- Cost-Effective: Renewing your existing tools through EDM is a cost-effective alternative to purchasing new ones. By extending the life of your tools, you can reduce your overall tooling costs and improve your return on investment.

- Extended Tool Life: Our EDM services significantly extend the life of your diamond cutting tools, maximizing your investment. By restoring tools to their original specifications, we help you get the most out of your equipment.

- Precision and Performance: The precision of the EDM process ensures that your tools maintain their cutting efficiency and accuracy. This precision is essential for achieving high-quality results in your machining operations.

- Custom Solutions: Our reboring and customized hole services ensure that your tools are tailored to meet your specific needs and machine requirements. These customizations can enhance the performance and versatility of your tools, allowing you to tackle a wider range of applications.

- Environmentally Friendly: By refurbishing your tools, we help reduce waste and promote sustainable practices. Renewing tools instead of discarding them contributes to a more environmentally responsible approach to manufacturing.

Why Choose Us?

-

At Nicolai North America, we combine advanced EDM technology with expert craftsmanship to deliver unmatched tool renewal services. Our commitment to quality, precision, and customer satisfaction sets us apart. When you choose us for your EDM services, you can expect:

- Expertise: Our team of experienced professionals has extensive knowledge and expertise in EDM and tool reconditioning. We stay up-to-date with the latest advancements in the field to provide you with the best possible service.

- State-of-the-Art Equipment: We use the latest EDM machines and technology to ensure the highest level of precision and efficiency in our services.

- Customized Solutions: We understand that each customer has unique needs. We offer tailored solutions to meet your specific requirements, whether it’s reboring, creating customized holes, or other specialized services.

- Customer Satisfaction: Your satisfaction is our priority. We work closely with you to understand your needs and ensure that our services meet your expectations. Our goal is to build long-term relationships based on trust and quality service.

Trust us to keep your diamond cutting CNC tools in peak condition, ready to tackle any job with ease. Contact us today to learn more about our EDM services and how we can help you achieve optimal performance in your machining operations.